The reliability of this fully automated take-up (Spulomat) has been proven by the fact that most units supplied to date have been placed in-line with extrusion lines in combination with an accumulator. Depending on the model various products can be wound onto spools, stretch wrapped, labelled and ejected ready for shipment.

The Spulomat offers many advantages, a few being:

- Simplified maintenance due to easy access to all components

- Low maintenance intensity

- User friendly due to its module design and the resulting easy set-up and string up

This innovative fully automatic take-up leaves a test end inside the spool of the conductor exposed for electrical testing even when used in- line with an extruder line. Owing to further development of the Spulomat, vHF offers the option of guiding all starting scrap and any faulty product into a container. This ensures only good product is wound onto the spool.

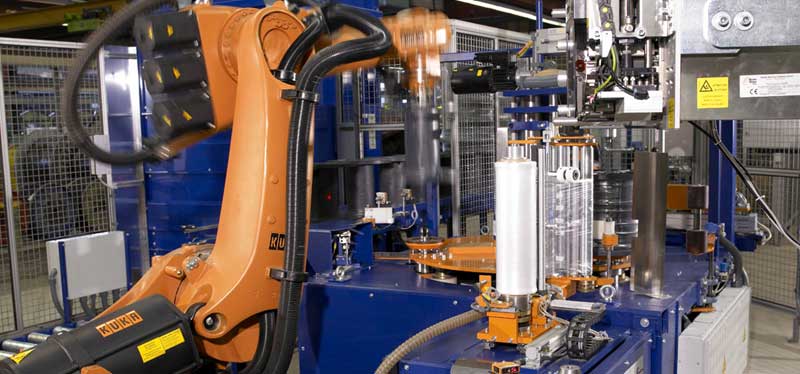

In additon using a handling system the Spulomat can be equipped with industrial robots for palletizing reels and reel handling. The first-time use of an industrial robot took place in the year 2013 and replaced the reels handling systems as well as the output magazine. The robot enables efficient and flexible reel handling as well as the mounting of intermediate layers on the palletized reels (flange face). Furthermore, the positions for the affixing of labels (optionally on the stretch film and or on the coil flange) are hit.

Product examples

- All

- Fully automatic Take-up